Tula India – Organic Desi Cotton, Handspun, Handwoven, Natural Dyed and Manual Tailored Clothing

- About Us

- Products

-

-

-

-

- WomenChoose from a wide range of colourful Tops/kurtis made using rainfed organic cotton, hand spun, hand woven, naturally dyed and manually tailored.

- MenFrom half sleeves to full sleeve shirts, short kurtas to long kurtas. Make your choice!

- KidsA wide collection of kids wear for boys and girls using the finest and softest cotton.

- BottomsChoose from our range of unisex pajams, Palazzo, Shorts, Towels and more

-

-

- Value Chain

- Ambassadors

- News

- Events

- Catalog

- Gift

- Gallery

- Contact Us

An Inspirational Journey to Learn About Khadi and Tula

I had the opportunity to visit Gandhigram, I heard a lot about the self-independent grama called Gandhigram. I was truly excited to explore and gain a deeper understanding of it. I work with TULA INDIA, a not-for-profit organization dedicated to collaborating with rainfed organic desi cotton farmers. which is then Ambar charkha handspun, handwoven, naturally dyed, and manually tailored textiles. Interestingly, one of our collaborated organizations manages the entire production process from cotton to fabric within their own village, and that village happens to be Gandhigram.

The route to Gandhigram from Dindigul station is amazing. The scenic beauty of the Western Ghats and its lush greenery is a sight to behold.

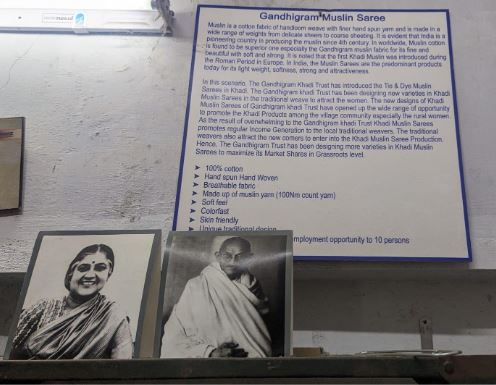

Gandhigram, located in Dindigul district, Tamil Nadu, is a hub of institutions that encompass a wide range of educational, healthcare, economic, and social activities. It stands as a dedication of Dr. T. S. Soundaram and her late husband, G. Ramachandran, who founded the Gandhigram Trust in 1947. Their commitment to serving the underprivileged is evident.

In 1976, the Gandhigram Rural Institute attained the status of a deemed university, and its various centers extend their support to the less fortunate, promote Khadi and village industries, and contribute to the self-sustainability of rural communities.

On my first day of visit, I had the privilege of seeing the Natural Dyeing Unit, led by Mr. Manikandan, a main pillar of the Natural dyeing unit in Gandhigram. He explained to me about his workspace. There were eye soothing colorful yarns all over. His table was filled with samples showcasing the raw materials used in natural dyeing, providing a fascinating glimpse into the origins of the colors and the dyed yarn.

As we conversed, Mr. Manikandan shared valuable insights into the intricate process, detailing the raw materials, mordants, dyeing techniques, and even his innovative experiments. It was a truly captivating experience.

Mr. Manikandan’s enthusiasm for their new Indigo Dye Project is very contagious. Here’s a description of the Indigo dyeing process and room preparation :

“In preparation for the Indigo Dye Project, a process is followed:

- Room Setup:

- The key to this setup involves the installation of around 15, four to five-feet-tall mud pots.

- Approximately four feet of each ‘pot hole’ is filled with goat dung, serving as insulation. This insulation helps maintain a consistent temperature of around 30 degrees Celsius.

- Another feet of each pot hole is filled with red sand.

- To top it off, a layer of cow dung is applied as a coating.

This carefully crafted the atmosphere for the Indigo dyeing process, ensuring optimal conditions for successful dyeing.

The figure illustrates the scouring process, which is typically the initial step in preparing fibers or fabrics for dyeing by removing impurities and natural oils.

The Vat Preparation process for the Indigo Dye Project involves these steps:

- Dyeing bath prepraration:

- Start by filling the pot with indigo, water, casitoria seeds, and lime.

- Fermentation:

- Allow the dye bath to sit undisturbed for the next 20 days. During this time, it will undergo fermentation.

- Vat is Ready:

- After the 20-day period, the dye bath will have fermented sufficiently and will be ready for use in the dyeing process.

- Dyeing Process:

- Depending on the desired shade, immerse the yarn into the dye bath.

- Subsequently, follow the oxidation process to achieve the color.

- Shade dry the yarn

This procedure ensures the successful preparation and use of the indigo vat for dyeing yarn, resulting in a wide range of beautiful blue shades.

Mr. Manikandan’s exploration of traditional solar dyeing is fascinating.

My second visit led me to the Pre Spinning Unit, where the transformation of cotton lint into sliver takes place. Lint is cotton after the seeds have been removed, and this intricate process is overseen by Mr. G. Murugan, operator of pre spinning process, expert with 35 years of experience.

The Pre Spinning Process happening in several stages:

- Cotton Bale: This marks the starting point, with cotton lint compressed into standard-sized bales weighing between 150 to 175 kilograms.

- Blow Room: The cotton lint from the bales undergoes initial processing in the blow room. Removes all the impurities. Opens the cotton and makes it fluffier.

- Carding: Subsequently, carding techniques are employed to further refine the cotton fibers.

- Draw Frame: The drawn cotton fibers are then processed through a draw frame.

- Speed Frame: Finally, the fibers are prepared in to slivers i.e. long continuous tapes for spinning on the speed frame.

This process is important in the journey from raw cotton bales to sliver.

1) BLOW ROOM : In the Blow Room, the primary objective is to open the bales of fibers and reduce the cotton tufts to their smallest possible size. This process serves several essential functions, including cleaning the fibers and removing any dirt, dust, and waste materials. The output from the Blow Room is Lap, as it prepares the cotton for further refinement in subsequent processing stages.

2) CARDING : The Blow Room process involves a series of dividing and redividing steps aimed at separating individual fibers. These steps help fibers to align parallel to each other but also effectively remove most of the remaining impurities present in the cotton. This process plays a vital role in achieving high-quality and purified cotton fibers.

3) DRAW FRAME : The Draw Frame process serves a crucial role in enhancing the quality of the roving while eliminating dust and impurities that may be present in the carded roving. This process involves two main actions: doubling and drafting.

- Doubling Process: Doubling is the initial step and aims to enhance the uniformity of the sliver, making it more consistent in terms of fiber distribution.

- Drafting: Drafting is the second action in the process, and it serves multiple purposes:

- Achieving maximum parallelization of fibers along the length of the sliver.

- Reducing the linear density of the roving.

- Combining 6-8 individual slivers into one, promoting better blending of the fibers.

Overall, the Draw Frame process is instrumental in refining and preparing the sliver for further stages, ensuring a high level of quality and purit

4) SPEED FRAME / SIMPLEX MACHINE : The Speed Frame process is responsible for reducing the roving weight to a suitable size for spinning into yarn while simultaneously inserting twist. This twist helps maintain the integrity of the draft strands. The output of this process is a sliver, which serves as the input material for the Ambar charkha, where it undergoes further transformation into yarn.

Our following visit was to the Ambar Charkha Spinning unit which is located in Dharmathupatti village, we met a group of 20-25 women spinners who create yarn as their source of livelihood, producing between 20 to 30 Hanks of yarn daily. Notably, after completing their household work and sending their children’s to school, they gather at the unit, spinning yarn until evening. Their joy in their work is evident, but what struck us the most was their incredible kindness. Throughout our visit, they were huddled together, engaging in quiet conversations, and as we were preparing to depart, one of them kindly invited us for coffee or juice. They pooled their money to offer us something, showcasing the unique warmth and generosity that one often finds only in villages.

During my next visit, I’ll be exploring the weaving unit in T Sublavaram, a weaving establishment with four decades of history. Mr. Shankar, the master weaver, shared with me that he joined this unit 38 years ago when it boasted 50 looms. However, at present, only 15 looms remain operational due to the migration of weavers to urban areas. Despite these changes, Mr. Shankar expressed his contentment in training numerous weavers throughout his career and finding joy in his work.

On average, the weavers here have the capacity to produce 8 meters of woven fabric per day.

The transformation of yarn into fabric in Gandhigram is truly inspiring, embodying sustainable livelihoods, contented artisans, and a remarkable spirit of decentralization. This village serves as a potent source of inspiration. A heartfelt thank you to Prasath Sir, Tula founder and the entire Gandhigram team for making this wonderful opportunity possible.

– Sushmitha R. K., Designer, TULA